Light sources have a significant impact on the design and operation of equipment in all industries.

From backlit avionics on airplanes to lighting components in medical devices, lighting brightness, color, temperature, and uniformity are critical to conveying visual information or helping users perform critical tasks. For example, the lighting in the cockpit of an aircraft must be bright enough and well distributed to allow the pilot to see important instruments while flying. Color also plays a little-known but crucial role.

The color rendering of organs and tissues at various light colors and temperatures affects the surgeon's ability to visually distinguish color differences that indicate tissue type and health. The lighting of medical devices and other devices used in healthcare must be within a specific color and temperature range to ensure that visual information is not misinterpreted. Achieving the desired performance of each light source requires measuring the luminosity characteristics of each light source, which are different for leds compared to halogen and incandescent lamps. Measurement solutions can help designers meet the desired light output, including emission Angle, color, reflection, contrast and pattern for a given application.

Description of the characteristics of the rainbow spectrum light source detection solution

hopoocolor solutions for light source measurement include luminosity and color measurement technologies - from angular measurement systems that measure light as an Angle factor, to non-angular measurement systems that measure brightness or overall lighting patterns.

These systems can be applied to design and quality control to complete all stages of light source manufacturing, from light source modeling and characterization to online production.

The choice to use a geodesic or non-geodesic system for photometry comes down to limitations on the measurement space and the range or type of measurement data that must be obtained.

Non-angular solution: Far field measurement

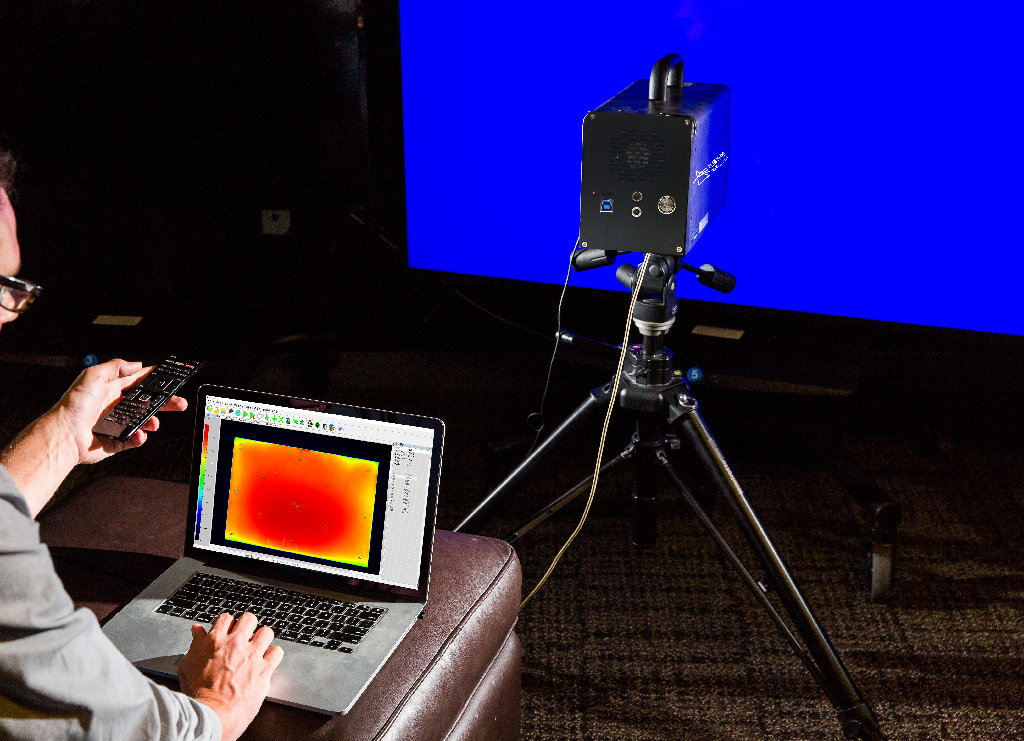

Non-angle-measuring solutions for iridescence color use imaging colorimeters or luminance meters to measure light sources by far field measurement methods. In far-field distribution measurements, the CXS imaging system can be mounted on a tripod and facing the horizontal plane to measure the light cast on a wall or through a diffuser. This allows the imaging system to collect illuminance distribution data and calculate the luminous intensity of the light source from a single measurement. This measurement method can be applied to a specified measurement space in the laboratory or on the production line. The measured values include luminous intensity (cd), which is the luminous flux (lm) in a given direction. The far-field measurement system measures the pattern of the light beam projected by the light source, so the size of the fixture itself (for example, the LED strip) does not affect the measurement data as it does in the near-field measurement scenario. The non-angle-measuring system generates the IES file and bitmap file of the lighting design (captured by the imaging system).

Features of far-field measurement system:

Use only imaging colorimeters or luminance meters

Measure the illumination distribution (beam pattern) of any light source (the size of the light source has no effect on the measurement of the beam pattern)

The complete characteristics of the output light source are measured at a single time

It can be used as quality assurance in mass production operation

Light can be projected onto a wall or screen to measure light (light source reflection)

Measurement of light by diffuser (light source propagation)

Direct measurement of LED arrays

Leds must be manufactured in full compliance with design specifications for chroma, brightness and color temperature.

Colorimeters and luminance meters combine advanced optical filters (unmatched match with CIE color matching functions) and proprietary calibration technology to provide the most accurate and complete measurement data from a single image. These systems take advantage of the speed and spatial efficiency of compact image-based systems (ideal for mass production lines) and are capable of simultaneously measuring hundreds or thousands of small light sources installed in LED arrays, PCBS or backlit components such as backlight devices (BLUs) and LED strips.

Angle measurement Solution: Near field measurement

The hopoocolor goniometry solution uses goniometers (SIG-400 for leds and small luminaires) to model light sources using near-field measurement methods.

The goniometer measures the luminance (Lv) and luminous intensity distribution (Candela) of the light source, calculating the spatial origin and Angle of the light emission - providing a complete understanding of the output of the light source seen at any distance.

Since the imaging system measures the precise spatial position and Angle of the light source, the size of the light source, such as the LED, affects the lighting pattern and thus the measurement data.